Product Model

10kV/20kV/35kV HORJT cable joint

HQRJT uses the same material and consistent specifications

key word:

layer

shield

structure.

Category:

Power new materials series

Hotline:

10kV/20kV/35kV HORJT cable joint

Text and image details

HQRJT Cable Straight-Through Splice: HQ-10/35-RJT-1X口口口口mm²

HQRJT Cable Straight-Through Splice: HQ-10/35-RJT-3X口口口口mm²

Product Features

● HQRJT uses the same material and consistent specifications as the cable for molding and injection splicing.

● HQRJT is a cable assembly with a stress-free cone and gap-free interface structure.

● HORJT significantly improves the reliability and durability of cable connections.

● HQRJT products comply with IEC and relevant national standards and have passed authoritative third-party testing, experiments, and expert identification of products and technologies.

Advantages of Cable Splice

● Firm connection, high conductivity, minimal loss, simple and fast

Cable Splice Construction Steps

1. The cable joint connects the cores through fusion welding. The copper core weld has no residue or pores. The tensile strength is 90%~92.5% of the original, and the conductivity of the welded conductor reaches more than 98% of the original conductor, with equal core and diameter.

2. The inner shield of the cable uses fusion splicing technology to "regenerate" the inner shield structure to the state of a new cable's inner shield structure.

3. The cable insulation layer uses fusion splicing technology to "regenerate" the cable insulation layer structure to the state of a new cable's insulation layer structure.

4. The outer shield layer of the cable uses fusion splicing technology to "regenerate" the outer shield layer structure to the state of a new cable's outer shield layer structure.

5. After connection via fusion splicing technology, the core, inner shield layer, insulation layer, and outer shield layer are ensured to be approximately equal in diameter after restoration.

6. The restoration method for the cable's copper shield layer, inner sheath, steel armor, and outer sheath is the same as for cold-shrink products. The copper shield layer and steel armor layer use braided ground wires for connection, fixed using constant-force springs. After fixing, waterproof tape is wrapped for another waterproofing treatment. Then, armor tape is wrapped to restore mechanical performance.

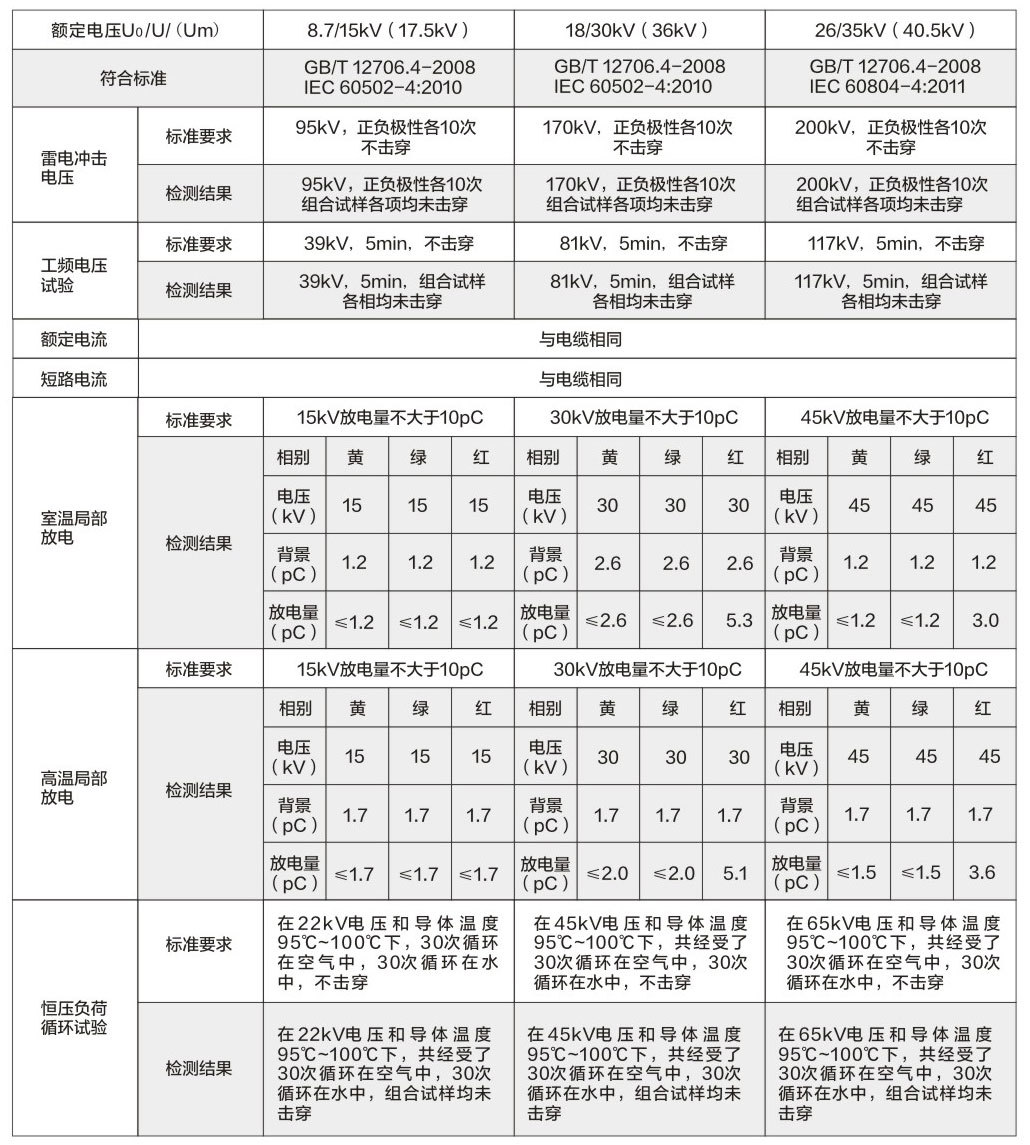

Technical Parameters

previous page

next page

OTHER PRODUCTS

ONLINE MESSAGE

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible